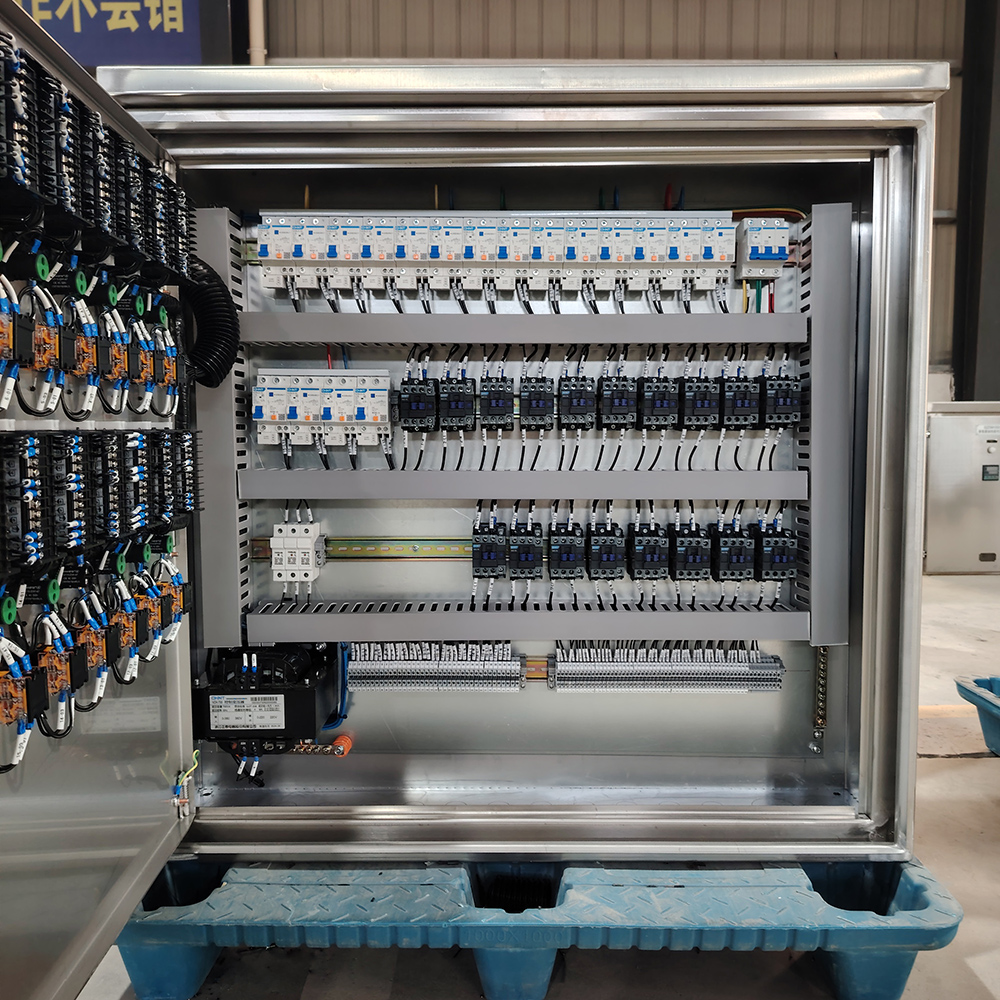

304 material double-layer door electric heat tracing control box with 18 circuits

18 circuits can meet very complex electrical heating needs. For example, in large chemical enterprises, refineries, or comprehensive industrial development zones, numerous pipelines, storage tanks, reaction vessels, and other equipment require different electric heating power and temperature control, and each circuit can correspond to a specific equipment or area separately.

1、 Characteristics of 304 material

Corrosion resistance

It performs well in various industrial environments, such as in factory workshops with chemical pollution, and can resist the erosion of substances such as acid, alkali, and salt. Even in environments with high humidity and the possibility of corrosive gases for a long time, 304 material can ensure that the control box casing is not corroded, thereby protecting the internal circuit components.

Mechanical performance

It has high strength and can withstand certain external impacts during transportation and installation without deformation. For example, at the construction site, even if accidentally dropped or collided with other equipment, it can still maintain its integrity well.

Good toughness, it can prevent internal components from loosening or being damaged due to vibration in environments where equipment is operating.

2、 Double layered door design advantages

Security guarantee

The outer door provides initial protection to prevent non professionals from accidentally touching the internal circuit. The inner gate further isolates critical circuit components. When conducting internal maintenance or adjustments, closing the inner gate can avoid the danger of short circuits caused by misoperation.

The space between the double layered doors can be filled with insulation materials to enhance the insulation effect. This helps to maintain temperature stability inside the control box and reduce the impact of external temperature changes on internal components, especially for some temperature sensitive electronic components.

Upgrade of protection level

This design helps to improve the overall protection level of the control box and meet the requirements for use in special environments such as humidity, dust, and slightly corrosive gases.

3、 Characteristics of 18 circuits

Application flexibility

18 circuits can meet very complex electrical heating needs. For example, in large chemical enterprises, refineries, or comprehensive industrial development zones, numerous pipelines, storage tanks, reaction vessels, and other equipment require different electric heating power and temperature control, and each circuit can correspond to a specific equipment or area separately.

It has more advantages in power allocation, as it can accurately allocate the power of each circuit according to the specific conditions of different heat tracing objects (such as material, size, required temperature, etc.), improve energy utilization efficiency, and ensure that each area can achieve the ideal heat tracing effect.

Diversity of Control Functions

Each circuit can be controlled independently. For some circuits that require extremely high temperature control, such as the electric tracing circuit around high-precision chemical production equipment, an intelligent temperature control system based on xj * * * can be used, combined with high-precision temperature sensors and complex control algorithms (such as PID control) to achieve accurate temperature regulation.

For some relatively simple application scenarios, such as the heat tracing circuit of some outdoor ordinary pipelines, basic fixed value control or timed control methods can be used.

4、 Key points for installation and maintenance

Installation points

The installation location should be chosen in a dry, well ventilated place, and kept away from flammable and explosive materials. If there are special environmental requirements, such as explosion-proof areas, installation must also be carried out in accordance with relevant explosion-proof standards.

Ensure a secure installation to avoid displacement of the control box or loosening of internal components due to vibration or other reasons during use. At the same time, grounding should be carried out in accordance with electrical installation standards to ensure the safety of equipment and personnel.

Reasonably plan the wiring to make the layout of the 18 circuits clear and neat, facilitating future maintenance and repair.

Maintenance points

Regularly inspect the 304 material casing for damage, corrosion, or other abnormal conditions, and promptly address any issues found.

Regularly inspect the internal circuits, including checking whether the wire connections of each circuit are secure, whether the fuses are working properly, and whether components such as relays and contactors are functioning properly.

When cleaning the control box, it is necessary to first cut off the power and use dry and soft tools for cleaning to avoid scratching internal components or causing short circuits.

- The last one:304 material double-layer door electric heat tracing control box with 16 circuits

- Next:no more

recommend products

-

304 material double-layer door electric heat tracing control box with 18 circuits

-

304 material double-layer door electric heat tracing control box with 16 circuits

-

304 material double-layer door electric heat tracing control box with 14 circuits

-

304 material double-layer door electric heat tracing control box 13 circuits